7 Habits of Highly Effective People® is a best selling business and self help book that targets three critical areas for personal development: Independence, Interdependence and Continuous Improvement. These lessons can be easily applied to almost everything you do. Let’s take a look at how they align with someone that is a buyer of an inkjet coder.

Independence

The first three habits focus on moving from dependence to independence.

1. Be Proactive

You’ve been putting off replacing that unreliable inkjet coder on your production floor. Don’t sit and wait in a reactive mode for another unplanned downtime to occur. Moments of downtime are easy to forget when things are working fine but also easily remembered in the weekly production review meeting. Depending on the production application, unplanned downtime can cost a company between $5,000 to $50,000 per hour.

2. Begin with the End in Mind

Envision want you want in the future and look at all products that need to be inkjet coded. Understand the packaged product’s journey throughout the supply chain to know what you need for ink requirements. Will the product be in a wet, humid environment or will it be chilled or frozen? Is the material you are printing onto a permanent part of the product package or is it removable? How long does the printed code need to survive?

3. Put First Things First

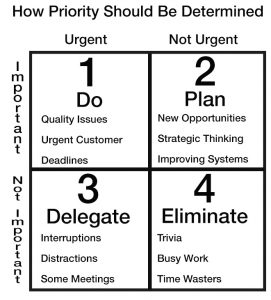

Understand the difference between what is important and what is urgent. When dealing with the mission critical in the production environment, use the following matrix to help prioritize the decisions you make and where to spend your time:

Customer deadlines and deliveries should be your highest priority. Make sure your equipment machinery does not interfere with the ability to deliver customer orders. Don’t plan on a maybe, plan on it being definitely.

Customer deadlines and deliveries should be your highest priority. Make sure your equipment machinery does not interfere with the ability to deliver customer orders. Don’t plan on a maybe, plan on it being definitely.

Interdependence

This next section deals with the dependence of two or more people or things on each other.

4. Understand Performance

It’s one thing to have the fastest carton erecting line or horizontal flow wrapper but if the ancillary equipment like the carton sealer, labeler or inkjet coder is not allowing you to achieve the promised output, then you’ve spent more money on performance than what you really need. Measure the performance of all supporting ancillary equipment and address those devices that can’t keep up. OEE is a good method to measure equipment effectiveness. For more information on OEE, visit oee.com.

We all know that interruptions with production equipment can occur for many reasons, so it’s good to understand during the buying process how fast you can recover from those “things” that are likely to happen. Ask your vendor and their referrals for the common things that go wrong and find out how fast the equipment can be recovered. Find out what it takes to start up a production run or to shut it down at the end of the run, what is the consumable yield and changeover time, and what level of maintenance is necessary.

5. Business Friendly

The business world has changed dramatically; e-commerce has enabled people to operate with more flexible hours outside the 8 AM to 5 PM working week. The process, reliability and trust of online ordering has become the norm thanks to the likes of Amazon and the Alibaba Group.

Traditionally, when purchasing an inkjet coder, a company would have to schedule sales representatives to discuss the application and recommend a solution. Scheduling time in your calendar to see multiple sales reps is just so time consuming. If a product needs face-to-face consultation, one must really ask the question, is the product really easy?

Find out if your vendor allows you to qualify your application online or place an order conveniently for equipment, parts or supplies? Are the consumable supplies or parts readily available and does the vendor offer free delivery?

Should you need help, can you call, email or have an online chat with the vendor? Do they offer an after hours number?

6. Innovate, But Keep It Simple

An inkjet coder is traditionally an electromechanical device that dispenses a solvent-based ink onto the target product for product coding. These conventional inkjet coders have many working parts, e.g., pumps, solenoid valves, switches, and filters. As technology improves, things should become less complicated, right?

It’s 2017! Your new inkjet coder should be ready for the future and not playing catch-up.

Investigate that the technology you are looking into is innovative and overcomes the hurdles that its predecessor was known for. Is there a paradigm shift in technology that results in less working parts, reduced maintenance, faster configuration or setup time? Is the inkjet coder an Industrial Internet of Things (IIOT) device, can it send SMS or email notifications, is there one ink that works well on all porous or non-porous substrates?

Search online for YouTube videos of the product in use to understand the ease of setup and operation. Use social media tools like LinkedIn to research the company and its human capital to know their areas of expertise and competency. Google search the company or product name and check for reviews.

Continuous Improvement

The final habit relates to continuous improvement of an effective buyer of inkjet coders.

7. Avoid the Distractions

Lead through innovation and never stop improving your productivity and bottom line. Competition is relentless so sharpen your saw and overcome the disruptions that get in the way of being productive. OEE measurement will help identify the plant floor priorities that you need to be working on. Remember, the most painful problem is not always the most expensive or hardest to resolve.

Since we’ve launched Redimark, we have helped many customers move from their failing continuous inkjet coders to the remarkably simple Redimark TC12 Thermal Inkjet Date Coder. For some buyers, there was hesitation based on the product’s low price. Can a printer with an introductory price of $1,495 really replace something they purchased for $8,000? It sure can! We anticipated some hesitation and for this reason, Redimark decided to offer a complete 30-day money back guarantee. Now there is no excuse not to remove yourself from the daily distractions and downtime you experience with your problem inkjet coder.

Redimark’s business caters to those looking for simplicity, convenience and greater productivity. With useful online product videos that help convey the Redimark TC12 Thermal Inkjet Date Coder’s product features and functions, simple operation and setup, there is no need to schedule sales reps for a product demonstration. Simply make your purchase of the Redimark TC12 and inks online, our online Product Advisor ensures your application meets the performance of the TC12 date coder.

We are very confident that your experience with Redimark will be one that is truly rewarding. We hope you will help us by sharing your experience and to influence others. To learn more about the TC12, visit redimark.com.

If you have any questions on any packaging topics, please don’t hesitate to send me a message at [email protected].

About Dean Hornsby

As Redimark’s Brand Evangelist, Dean is a passionate guy. Passionate about sharing his deep knowledge about packaging and automation, passionate about exceptional customer satisfaction, and a bit nutty about perfectly printed date codes. Nothing makes him happier than matching Redimark’s solutions with your business’s coding and marking needs (well, that and a good craft beer). In his more than 25 years in the Fast-Moving Consumer Goods (FMCG) industry, Dean has done and seen it all; from engineering to plant automation to vision and coding systems. Have a question for Dean? He’d love to chat.