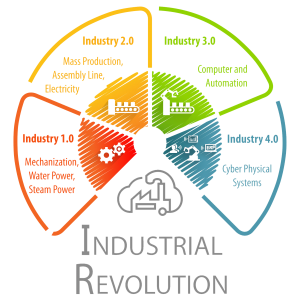

Industry 4.0 is considered to be the 4th level of industrial revolution. 1.0 was the era of mechanization; 2.0 saw mass production; in 3.0 came the introduction of automation. Industry 4.0 is about digitizing the enterprise ecosystem with system interoperability, cloud-connectivity and the Internet-of-Things.

The four levels of Industry 4.0.

So what does Industry 4.0 have to do with consumer product manufacturers packaging production lines? The focus here is on essential process functions in order to reduce steps, mitigate errors, increase productivity, and yield greater efficiency from connecting packaging machinery hardware with software products and relevant user entities via the cloud.

Industry 4.0 is the technology framework designed to turn manufacturing environments into “smart factories” and offer the same benefits that our connected devices, such as smartphones, social networks, and home automation appliances have delivered in our personal lives for the last 10 years. This same technology is now migrating into the workforce and will change the way we all work today and in the foreseeable future.

Industry 4.0 is having a positive impact with consumer product manufacturers in many different areas of the business process. How, you may ask? Let’s start with social networks. By analyzing user behavior on social networks, producers of consumer products can rapidly survey the social community through likes and dislikes and bring to market products that appeal to consumers. Now, let’s look at rapid product development. Package design teams that create innovative package containers are collaborating in remote locations and using 3D printers and digital inkjet printing presses to reduce tooling steps to go from screen to machine. This enables them to provide low-cost customization while reducing the time to market. What this all means is that production costs are lowered, products reach the market faster, and innovation aspires to new heights.

Industry 4.0 Key Benefits

Throughout the supply chain, Industry 4.0 tightly integrates the vertical and horizontal partners through system interoperability. The benefit is greater data visibility, lower administrative costs and overall improved communications.

In the consumer product manufacturing environment, smart factories in Industry 4.0 will benefit from using standard system protocols which eliminates the need for software customization of packaging machinery. Standard system protocols enable autonomous data capture of production and process data. This type of data is sent to the cloud to produce reports, report live notifications and help predict downtime by scheduling preventative maintenance.

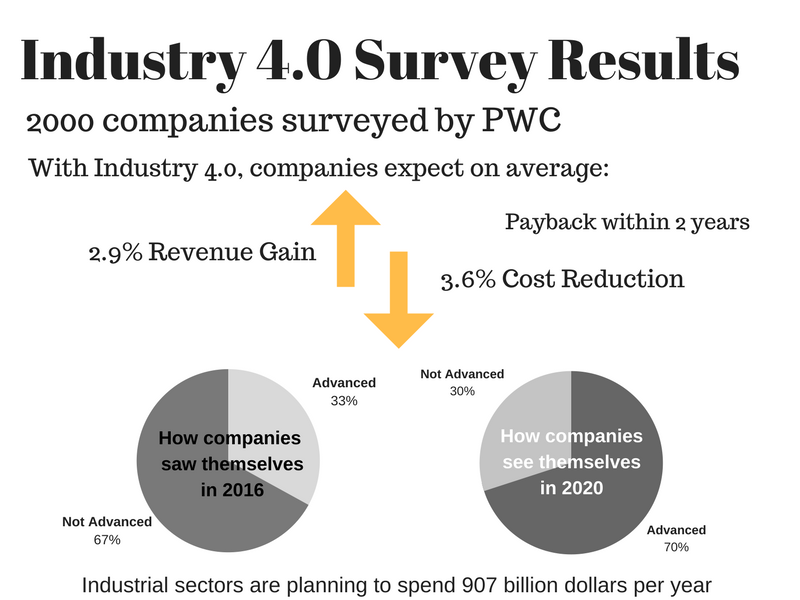

A study by PricewaterhouseCoopers (PWC) in 2016 revealed that out of 2,000 companies surveyed, just 33% rated themselves as being advanced. This number jumps to 70% when looking ahead to 2020. Industrial sectors are planning to invest US$907 bn per annum (approximately 5% of revenue) into Industry 4.0 and 55% percent of these companies expect a payback within two years.

How you might benefit from Industry 4.0

Financial Performance Improvement

The efficiencies gained through process reduction curtail manufacturing costs and deliver value to customers, which increase earnings. PWC businesses that were surveyed expect an average of 3.6% cost reduction and a revenue gain of 2.9%. It’s no longer a choice to look at top or bottom line results. Industry 4.0 has a positive impact on both.

Deeper “Digital” Customer Relationships

Customer relationship management in Industry 4.0 is customer-centric. Online data collection tools analyze consumer’s social interest, browsing behavior, and buying habits. Data collected is gathered to build personas that help product marketing and development teams achieve a level of product customization that drives sales growth.

To successfully understand the needs of customers, a company needs to have resources that are capable of analyzing the “digitized” data collected. Companies that respect Industry 4.0 are actively making human resource investments in this area to define customer requirements and to better understand their behavior.

Accelerating Global Presence

Digitizing the enterprise system means opening doors to new global business opportunities and supporting their operational efforts on the back-end with efficient supply chain logistics. Industry 4.0 technology solutions deliver greater visibility and interoperability to all parties. This means that companies can gain a presence into a market or region that might previously have struggled due to barriers of entry.

The Connected Workplace

There is a driving force for IT self-sufficiency among employees that own their own personal smart device such as a phone or tablet. These employees want to access data or connect to equipment within the workplace. With new packaging equipment technology that is part of the Internet of Things (IoT) community, Apps enhance the user experience and enable employees to work remotely with greater flexibility and convenience. Tools for smart devices provide insight into production equipment for troubleshooting support, allow customers to share documents or images, or provide live video feed to help communicate effectively. Smartphone push notifications provide real time alerts to address mission critical events and reduce downtime.

A good example of this is when Redimark designed the TC12 inkjet coder, it intentionally deployed M2M cellular technology and Ethernet WIFI in the device to remove any internal IT obstacles for cloud connectivity. Cloud connecting the Redimark TC12 inkjet coder provides live alert notifications to users, and enables smartphone apps to directly connect with the TC12 device. Cloud connectivity also creates the pipeline from the TC12 inkjet coder to a cloud server so that production SKU information can be collected for live and historical data views.

Artificial Intelligence (AI)

Concept about machine learning to improve artificial intelligence ability for predictions

AI software algorithms will impact many areas in Industry 4.0 Smart devices and machinery will perform predictive analytics in order to optimize schedule maintenance to prevent catastrophic breakdowns.

Computer logins or personal preferences will be established using biometrics or facial recognition. E-commerce algorithms will analyze purchasing behaviors to suggest other products that consumers with similar needs had purchased. Expect to see major development and deployment with AI in the coming years.

Is Your Marking and Coding Device Industry 4.0 Ready?

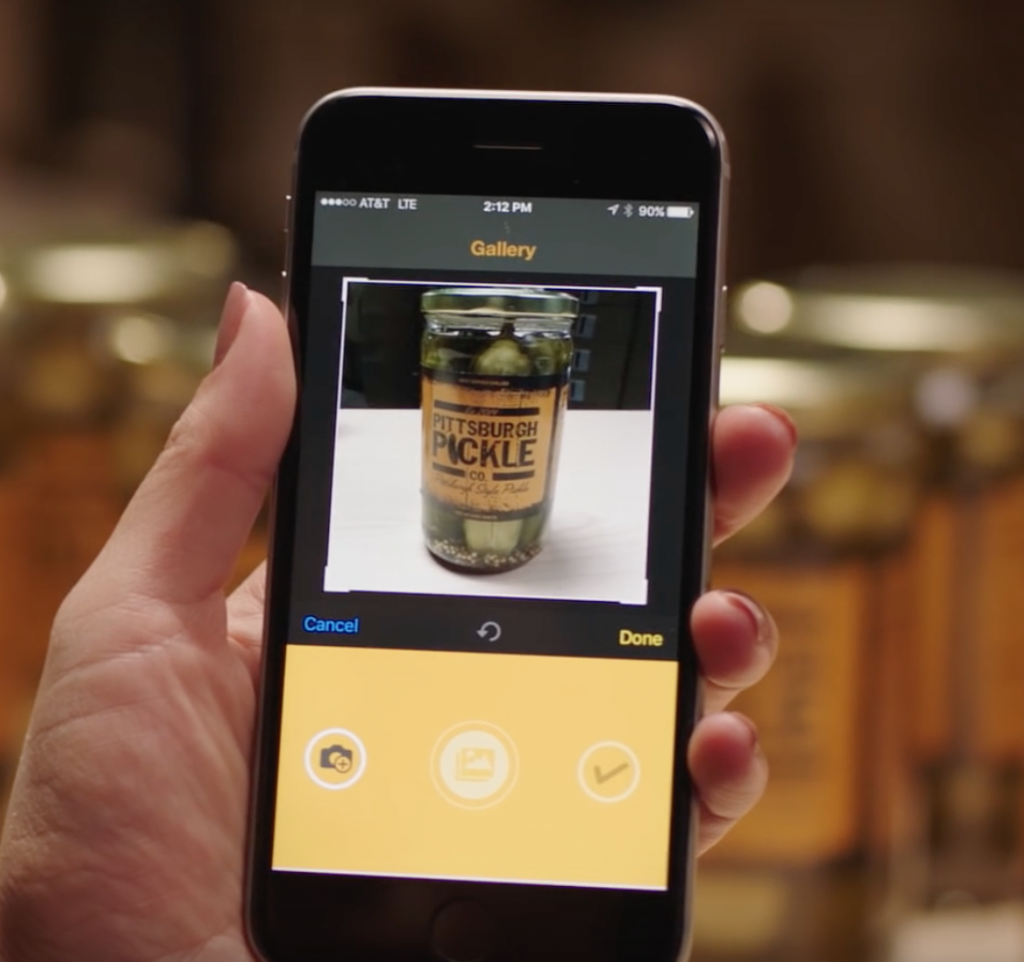

The Redimark TC12 is an IoT industrial inkjet coder that enhances the user experience with the cloud-connected web portal and a smartphone user App.

The Redimark App means that users can send photos of packaged products to the printer’s library for a visual reference to simplify the coder setup or setup device preferences. The web portal enables customers to track orders of printing supplies, interact with the help desk using online chat, and setup notifications to receive text messages or emails of printer performance and status. Because the software products are cloud-based rather than device based, Redimark’s software releases and implementation are effortless.

The industry benefits herein are no longer the vision of a futurist – this is all happening right now through Industry 4.0 and it is playing a huge part in advancing consumer product manufacturers as efficient market leaders. Industry 4.0 benefits business operations of all sizes and its migration into businesses is inescapable. The investment costs are low for yielding high productivity gains. The financial results will be rewarding if deployed correctly. With Industry 4.0, we will see a transformation of manufacturing like we have never seen before.

About Dean Hornsby

As Redimark’s Brand Evangelist, Dean is a passionate guy. Passionate about sharing his deep knowledge about packaging and automation, passionate about exceptional customer satisfaction, and a bit nutty about perfectly printed date codes. Nothing makes him happier than matching Redimark’s solutions with your business’s coding and marking needs (well, that and a good craft beer). In his more than 25 years in the Fast-Moving Consumer Goods (FMCG) industry, Dean has done and seen it all; from engineering to plant automation to vision and coding systems. Have a question for Dean? He’d love to chat.